Materials

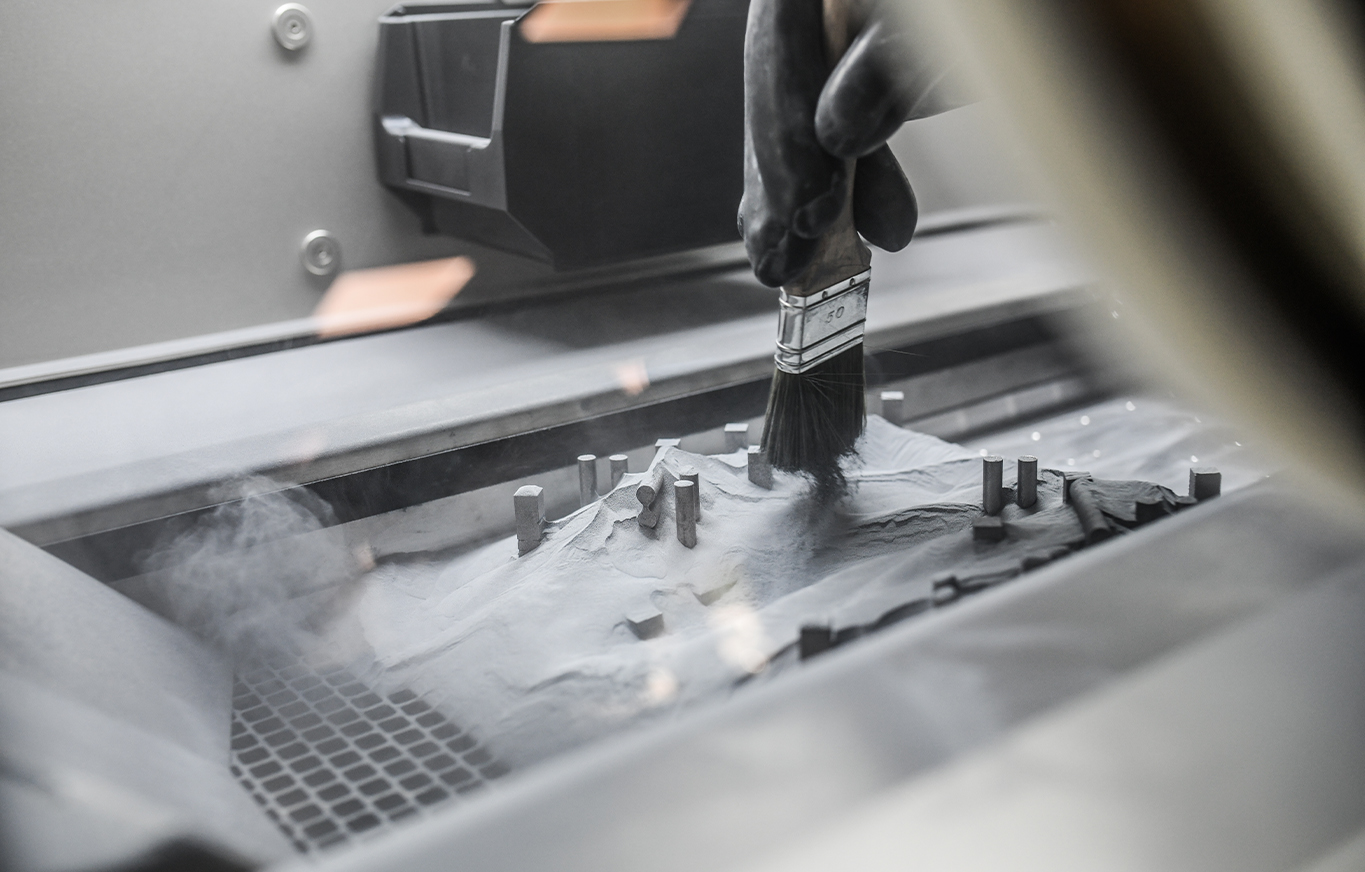

Norm Additive has systems in the field of metal and polymer additive manufacturing. Currently, serial production is carried out with aluminum and steel alloys and PA12 polymer materials in our production facilities. According to customer needs, different types of alloys and polymers can also be produced and solutions are offered to our customers in a wide range of materials.

AlSi10Mg

AlSi10Mg alloy is highly demanded for many applications in automotive and aerospace industries due to its lightweight, high specific strength and weldability. This hypoeutectic alloy has been object of a strong focus in additive manufacturing for many years owing to its generally good castability, high melt fluidity, low solidification shrinkage and low risk of hot cracking. Small quantities of magnesium and iron increases the strength of the alloy at both ambient and elevated temperatures, and also make the alloy to be more responsive to the heat treatment. The alloy is used in fabrication of machine parts, rocker arms, timing gears, compressor cases, fuel pumps, air compressor pistons, aerospace components, high speed rotating parts, crankcases, and engine cooling fans.

“Additive manufacturing uses less materials, labor and energy, but has a higher impact than traditional manufacturing.”

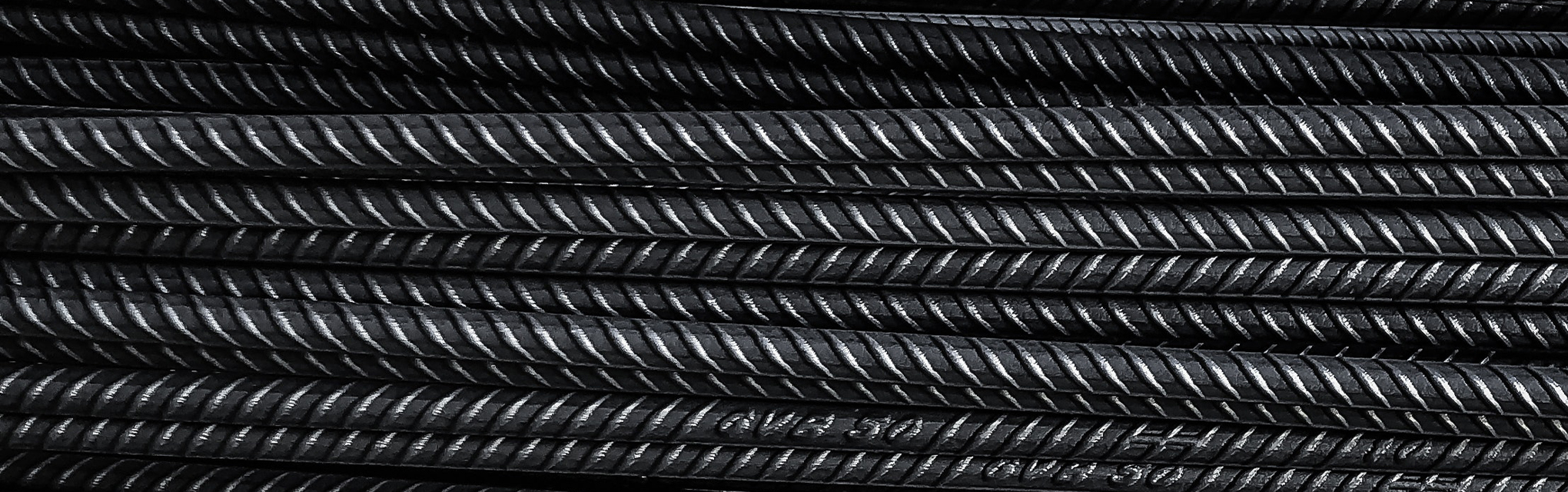

316L Stainless Steel

316L is a molybdenum-containing austenitic stainless steel that is more resistant to atmospheric corrosion and pitting/crevice corrosion than conventional chromium-nickel austenitic stainless steels. This alloy offers excellent formability and manufacturability. Molybdenum content provides high creep resistance and tensile strength at high temperatures. 316L is commonly used in chemical and petrochemical industry, automotive parts, photography equipment, in food processing, pharmaceutical equipment, and medical devices, in water treatment, marine applications and architectural applications near the seashore or in urban areas.

Polyamid 12

Polyamide 12 has a wide application area thanks to its many physical properties such as low density of 1.01 g/cm³, high abrasion resistance, high shore hardness and low water absorption. PA 12 used with HP Multi Jet Fusion printers; It makes it possible to present less porous and detailed surfaces than parts produced by other methods. In addition, due to the surface structure, paint etc. Its adhesion to substances ensures a good product. It is very useful for functional prototypes, low volume mass production and final product.